Project-Based Financial Modeling: Why Automotive Tooling Needs Its Own Modeling Playbook

If you run an automotive tooling business, you already know: forecasting feels less like math and more like juggling flaming chainsaws.

One month, you’re lining up steel orders at one price, the next month the supplier calls to say, “Actually, double it.” Projects stretch across months (or years), and every job is unique. On top of that, customers' invoicing is timed with milestones that may or may not line up with your cash needs.

Traditional income statements weren’t built for this reality. They make it hard to see which projects are quietly eroding margins or draining cash.

Wish you had a crystal ball? Here’s something even better:

Project-Based Financial Modeling

Note: This post goes into depth about financial models and assumes you like to build complicated spreadsheets, so if that makes your eyes glaze over, send it to your CFO. Even better, let us be your fractional CFO so that you never have to hear phrases like “revenue recognition rules” again. You can let us do the financial modeling and give you the exact information you need in a clear, straightforward way.

Fellow formula nerds, let’s dive in.

Why modeling projects beat guessing

At its core, project-based modeling forces you to look at each job not just as “revenue in/revenue out,” but as a mini business with its own cash flow, profitability, and risks. When done right, the model gives you:

A clear picture of which projects are creating value and which are bleeding you dry.

A way to align billing schedules with project progress (and avoid being the bank for your customers).

The confidence to invest in equipment, people, or facilities without relying on gut feel.

As the saying goes, “In God we trust; all others bring data.”

Building the model for an automotive tooling company (without losing your mind)

Think of the model as a layered cake: each layer builds on the last, and if you skip one, the whole thing collapses.

Step 1: Backlog and pipeline

Start with what you already know — your awarded jobs. This is your backlog, your “done deal” work. Then, layer in your pipeline of quotes and opportunities. But don’t fall into the trap of treating every RFQ (Request for Quote) as guaranteed revenue. Weight them by probability.

For example, if you’re chasing a $1 million program and you estimate a 50% chance of winning it, add $500,000 to your forecast. It’s not pessimism — it’s realism. Think of it as putting the right odds on the horse you’re betting on.

Step 2: Revenue recognition rules

This is where finance meets reality. Decide how you’ll recognize revenue: percentage-of-completion (spread across phases), milestone billing (specific deliverables trigger invoices), or delivery-based (the “all at once” method).

Example: a $2 million tool might pay 30% when the project kicks off, 40% at customer tryout, and the final 30% at delivery. Without these rules, your model is just numbers in a vacuum. With them, you can actually match revenue to effort and see if your income aligns with the work being done.

Step 3: Cost profiles for each project

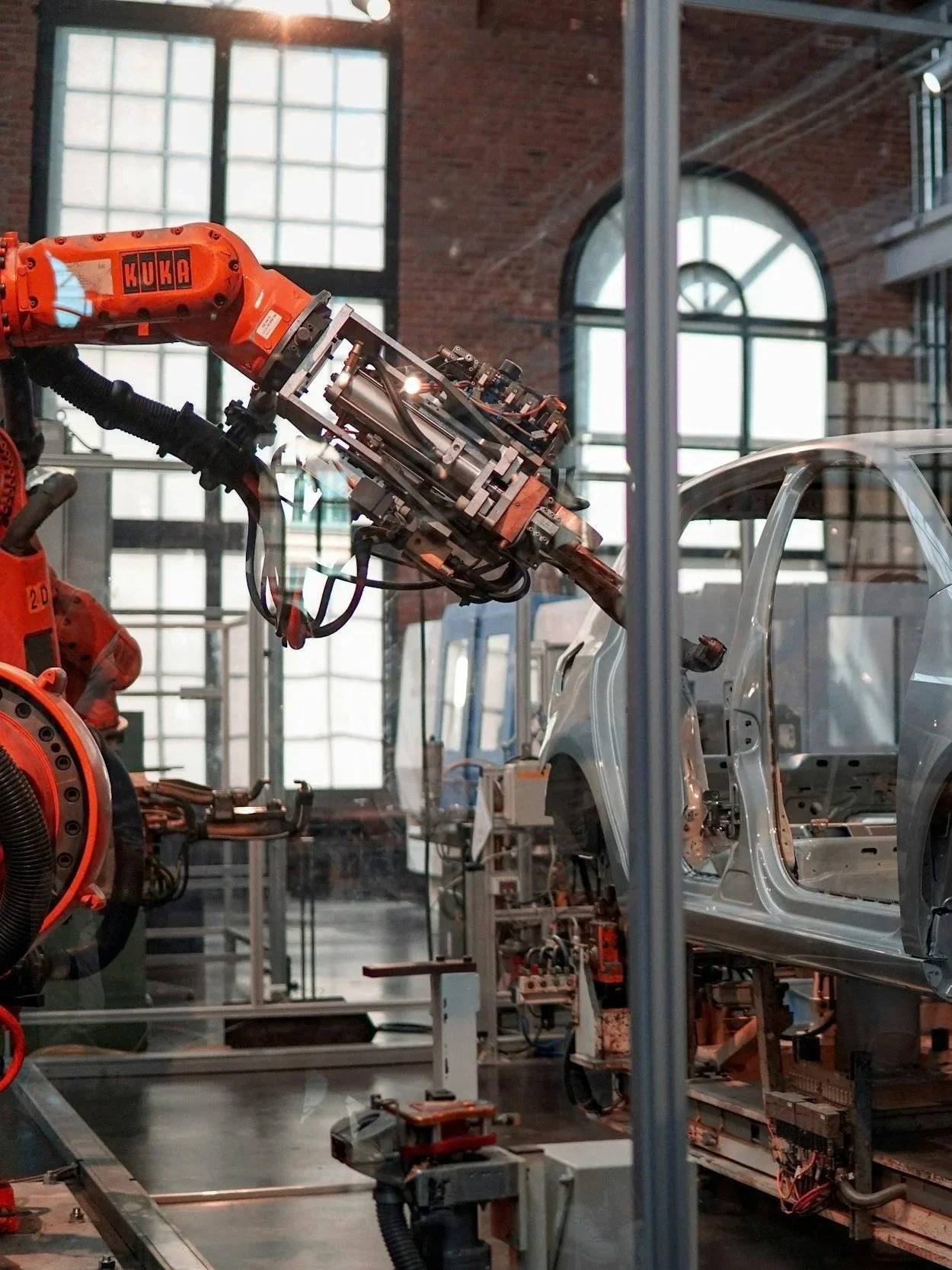

Both peaks and valleys need to be considered in your tooling program.

Every project has its own rhythm of spending. Materials might hit in month 2, machining costs pile up in months 2–4, and engineering hours stretch across the entire project. Laying these costs out over time gives you visibility into when cash goes out the door.

Picture it this way: a tooling program isn’t one giant bill — it’s a series of peaks and valleys. If you only budget for the final peak, you’ll miss the valleys that drain cash in the meantime.

Step 4: Overhead and capacity

Here’s where things get tricky. Your engineers, machines, and shop space are shared across projects. Allocating overhead fairly and spotting bottlenecks is critical.

Example: Two projects may look fine on paper until you realize they both need the same five-axis machining center in the same week. The model should surface these conflicts early, so you can adjust schedules, add capacity, or have a tough conversation with sales.

Step 5: Forecast cash flow

This is the heart of the model. Pair your billing milestones with when you actually pay suppliers and employees. Suddenly, you’ll see the dips — those weeks when payroll is due but the customer hasn’t cut the check yet.

This is also where you figure out if you’ll need short-term financing. It’s not about guessing whether you’ll run short; it’s about knowing when and planning ahead.

Step 6: Run “What-If” scenarios

No plan survives contact with reality. That’s why scenario planning is so powerful. What if a customer delays a tryout by two months? What if steel prices spike 15%? What if a project gets canceled halfway through?

Running three versions — conservative, base, and aggressive — gives you guardrails. Instead of being surprised, you can say, “We already modeled this, and here’s how we’ll respond.” That turns uncertainty into strategy.

Step 7: Roll up into company-wide financials

Finally, take all those project-level forecasts and roll them up into a company-wide view: P&L, balance sheet, and cash flow. This is the bridge between the shop floor and the boardroom. It gives leadership a holistic picture while still letting project managers track performance at a granular level.

Think of it as zooming in and out on Google Maps. One moment you’re at street view looking at Project A, the next you’re at satellite view seeing how all projects impact the company’s financial health.

The payoff of financial modeling in Automotive Tooling

This isn’t just an exercise in spreadsheets. A well-built model is a decision-making tool. It tells you whether to speed up, slow down, or even walk away from a project. It makes sure your best engineers aren’t tied up on jobs that won’t make money. And most importantly, it shines a light on cash — because in tooling, profitability without liquidity is just theory.

Or to borrow a line from Warren Buffett: “You only find out who is swimming naked when the tide goes out.”

A project-based model keeps your trunks firmly in place.

Final thought

If your financial reporting still treats projects like they’re all the same, it’s time for an upgrade. Start small: model one job from kickoff to delivery. Layer in the costs, the billing milestones, and the overhead. Then expand. Soon you’ll have a model that doesn’t just explain the past — it guides your future.

And the next time steel prices jump or a customer delays a tryout, you won’t need a crystal ball. You’ll already know what it means for your business.

If you’d like help creating models that make sense for your business we are here to help.